Contact

Listening to your spring design needs.Types of Springs

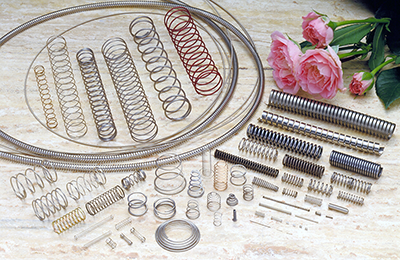

A thousand technologies for a thousand applications.

TORSION SPRING

A torsion spring is a spring that is subject to

twisting load (torque) about the axis of a coil.

Manufacturing performance Wire diameter : 0.03㎜〜1.8㎜

COMPRESSION SPRING

In this type of spring, also generally known as a pushdown spring, the compression load (the load on the coil axis) and the deformation are proportional.

Manufacturing performance Wire diameter : 0.02㎜〜1.5㎜

Shape track record : long winding coils、conical、barrel、

irregular pitch, irregular outer

diameter

TENSION SPRING

A tension spring can be thought of as essentially the same

as a compression spring (the coil is generally a tight coil).

Manufacturing performance Wire diameter : 0.08㎜〜0.7㎜

Material

| Type | Piano wire, Stainless steel wire, Platinum wire, Phosphor bronze wire, Various plated wires, etc. |

|---|---|

| Shape | Round wire, Flat wire |

Example of Built-in Products

Used in various products| Electric Devices | Industrial Products, Home Devices, Cameras, Printers, Gas Devices, Fire Alarms, Electricity Meters, etc. |

|---|---|

| Telecommunication Equipment | Mobile Phones, Charging Stands, Terminal Blocks, Watches, etc. |

| Medical Equipment | Catheter Therapy Device, Endoscopy Device, Electric Knife, Biopsy Device, Health Device, Sphygmomanometer, Pulse Oximeter, Weight Scale, Pedometer, Barber Device, etc. |

| Vehicle Equipment | Cars, Motorcycles, Mowers, Bus, etc. |

| Other | Jewelery, Locks, Audio Equipment, Fishing Gear, Stationery, Toys, Furniture, etc. |

Usage

Meeting each need, fitting each application.| Electric Device: | Switches, Connectors, Battery energization, Energizing parts, Contact probe, Printer dot pins, Sensors, etc. |

|---|---|

| Communication Equipment, watches, Camera: | Watch crown, Watch day turning, Hinge, Antennas, Camera shutters, Around camera lenses, etc. |

| Medical equipment, Health equipment: | For guide wires, For endoscope insertion parts, Projection markers, Clips, Biopsy machines, etc. |

| Cars, Motorcycles: | For carburetors, In-car electrical components, Meters, Brake switches, etc. |

| Others: | Filters, Fasteners, Earrings, Arm support for record needles, Lure frame, Reel, Stationery clips, Ballpoint pen parts, etc. |